News Center

Aluminium oxide for Refrigeration System

Applications

DRIER-RECEIVER TDS MSDS

The product has passed the Interetek laboratory refrigerant compatibility test

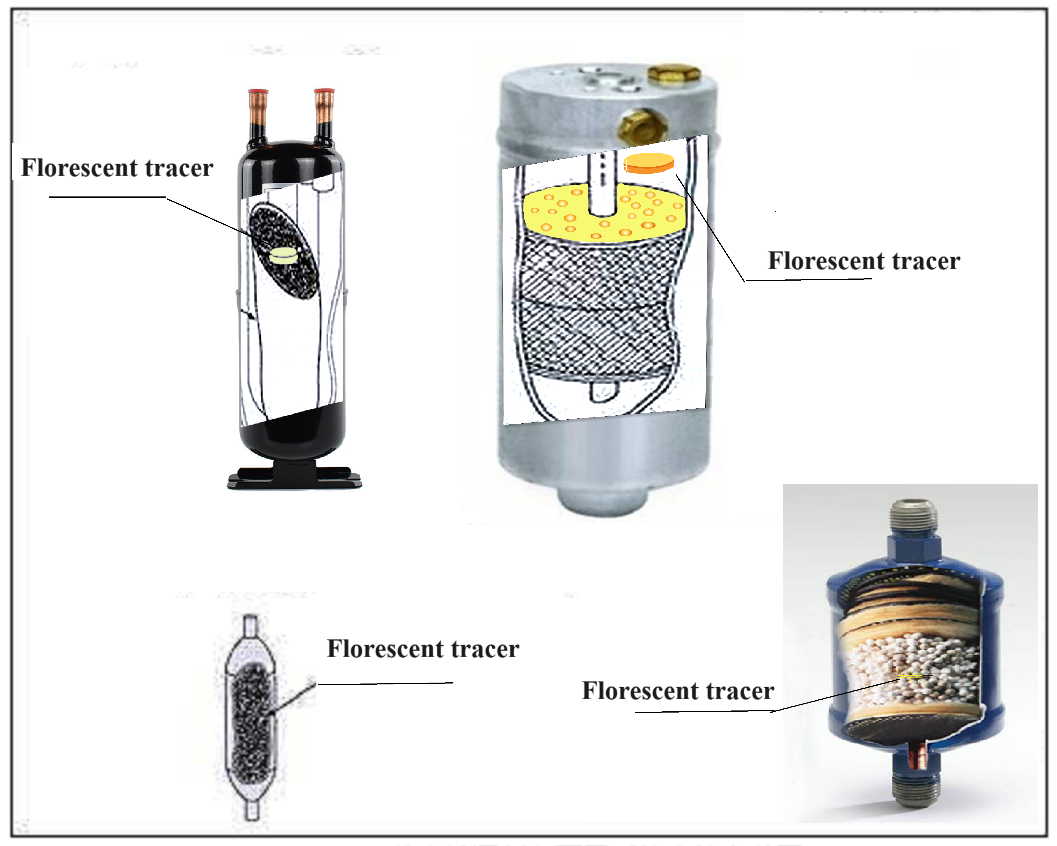

Tracer ChuangGe Fluorescent tracer provide a perfect solution for using fluorescent leak detection agents on automotive air conditioners.Tracer ChuangGe Fluorescent tracer is a type of absorbent felt used as a carrier to load fluorescent leak detection agent. Fluorescent tracer can be easily added to components of air receiver drier, and can also be directly placed in drying tanks or reservoirs. After the final assembly and operation of the air conditioner, the fluorescent leak detection agent will be smoothly released through the operation of the refrigerant and lubricant.

Typical properties

Typical properties | CGY-65 | CGY-95 | CGY-130 |

Tablet diameter | 6.53mm | 9.52mm | 13.05mm |

Detection wave length | 365nm | ||

Flash point ASTM D-3278 | ≥100℃ | ||

The viscosity of polymerized tracer 25℃ Mpa.s | ≤60℃ | ||

PH | 7-8 | ||

Characteristics of Tracer ChuangGe

1.The addition of solid flakes is very simple, avoiding the splashing of fluorescent agents without changing the original production line

2.Long term presence in refrigerants can be used for leak detection and online quality control within and outside the warranty period

3.Very accurate, can use UV light to accurately identify all leakage points

4.This product is green, environmentally friendly, and pollution-free, controlling refrigerant leakage and protecting the environment

Packaging method

◆ 500p/2000p per box

◆ Vacuum sealed bag with one-year shelf life

Aluminium oxide (Al₂O₃) is a highly versatile and durable material commonly used in refrigeration systems to improve their efficiency and performance. Known for its excellent thermal conductivity, high insulation properties, and resistance to corrosion, Aluminium oxide for Refrigeration System is an essential component in various refrigeration applications. It is widely utilized in heat exchangers, evaporators, and other critical system components where efficient heat transfer and durability are paramount.

In refrigeration systems, Aluminium oxide for Refrigeration System serves multiple roles. Its thermal conductivity ensures that heat is effectively absorbed or dissipated, maintaining optimal temperatures and enhancing the overall cooling performance. Moreover, aluminium oxide’s high resistance to corrosion and wear makes it particularly valuable in environments where moisture, refrigerants, and other chemicals are present. This ensures that refrigeration systems maintain their longevity and reliability even in demanding conditions.

In addition, Aluminium oxide for Refrigeration System is chemically stable and can withstand extreme temperatures, making it ideal for use in both low and high-temperature refrigeration systems. Its non-reactive nature also ensures that it won’t interfere with the refrigerants used in these systems, maintaining the purity and efficiency of the cooling cycle.

In conclusion, Aluminium oxide for Refrigeration System plays a crucial role in the development of modern refrigeration systems, offering benefits in terms of heat transfer efficiency, corrosion resistance, thermal insulation, and environmental sustainability. Its wide range of applications makes it an indispensable material in ensuring the optimal function and longevity of refrigeration equipment across various industries.

Dalian Chuangge Technology Co., Ltd

Richard Han

Doris Zhou

Headquater: 9th Floor, Century Classic Building, No.10, Xinghai Square, Shahekou District, Dalian City, Liaoning Province

Copyright: Dalian Chuangge Technology Co., Ltd. Business License Privacy Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.